Jiangsu TRSK

New Material Co., Ltd.

0

0

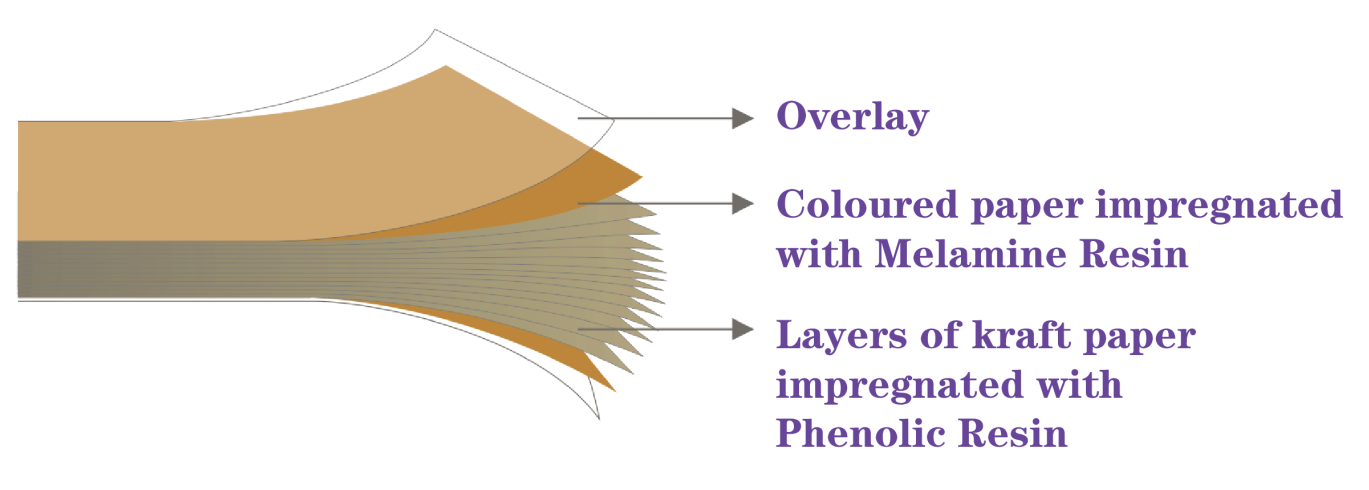

Dogbone White Wood grain High pressure laminates are manufactured using layers of Kraft paper impregnated with phenolic resins, decorative paper impregnated with melamine resin and printed decors which are protected using durable overlay covering. Resin impregnated layers are fused together under high pressure and temperature to activate the melamine and phenolic resins resulting in a robust fused waterproof surface.

| Material | Printed Décor paper, Kraftpaper, Phenol resin (100%), melamine (100%). |

| Color | Woodgrain. |

| Size | 2440x1220mm |

| Main Thickness | 0.7mm, 0.8mm, 0.9mm, 1.0mm. |

| Surface finish | Texture. |

| Quality | · Quality Standards: NEMA LD 3-2005, EN 438-7:2005. |

| · QC follow from impregnating to packing | |

| · Accurate cutting as per order | |

| · Color Variation: we try our best to control the color variation | |

| · Thickness tolerance: -5% +5% | |

| Usage | Widely used in interior applications (tabletop, wall covering, countertop). |

| Packing | In strongly seaworthy wooden crates. |

| Delivery | 20 days after receiving deposit. |

Packaging:

1. 12 packages per 20' container;

2. Package material: solid wood, plywood;

3. Each package can weigh 1600 KGS = 516 PCS of 4'*8'*0.7mm

| Testing item | Unit | Permitted value | Testing result | Judgment | |

| Resistance to cigarette burns | —— | ≥ 2 grade | 1 grade | Pass | |

| Impact resistance | fall highness | cm | ≥100 | 100 | Pass |

| dent diameter | mm | ≤10 | 8 | ||

| showing | —— | ≥2 grade | 1 grade | ||

| Resistance to cracking | —— | ≥2 grade | 1 grade | Pass | |

| Resistance to dry heat | showing brightness | —— | ≥3 grade | 1 grade | Pass |

| other | ≥2 grade | 1 grade | |||

| Abrasion resistance | r | ≥350 | 870 | Pass | |

| Resistance to boiling water | quality increase | % | ≤10 | 6.6 | Pass |

| thickness increase | % | ≤12 | 8.9 | ||

| showing | —— | ≥2 grade | 1 grade | ||

| Tensile strength | MPa | ≥55 | 63 | Pass | |

FAQ:

About HPL

Q: Is thickness really 0.7mm?

A:Precisely it goes between 0.67mm and 0.72mm.

Q:Is this shipped flat or rolled up?

A:Flat.If you order samples, we will ship rolled up.

Q:Can this be used as flooring?

A: Absolutely not. If you want to apply it for flooring.Wear layer of higher level must be added in the production process.

Q:What kind of substrate works the best for this laminate?

A:The substrate(the material the laminate is glued to) is generally either plywood or MDF(medium density fiberboard).

Q:Is this product flexible? Can it be glued/secured to a curved surface?

A:Yes,it can be glued to a surface with radius but does have its limits:If you require a greater flexibility, we recommend you to buy postforming Laminate.

About Factory

Q:How many people in your factory?

A:More than 200.

Q:When was your company founded?

A:Our company was founded in 1998.

Q:What's your main products?

A:Our main products including HPL,Compact panel,Medical Panel,Chemsurf panel,Antibacterial Panel,Cladding Panel,Postforming Panel,Solid core Panel.